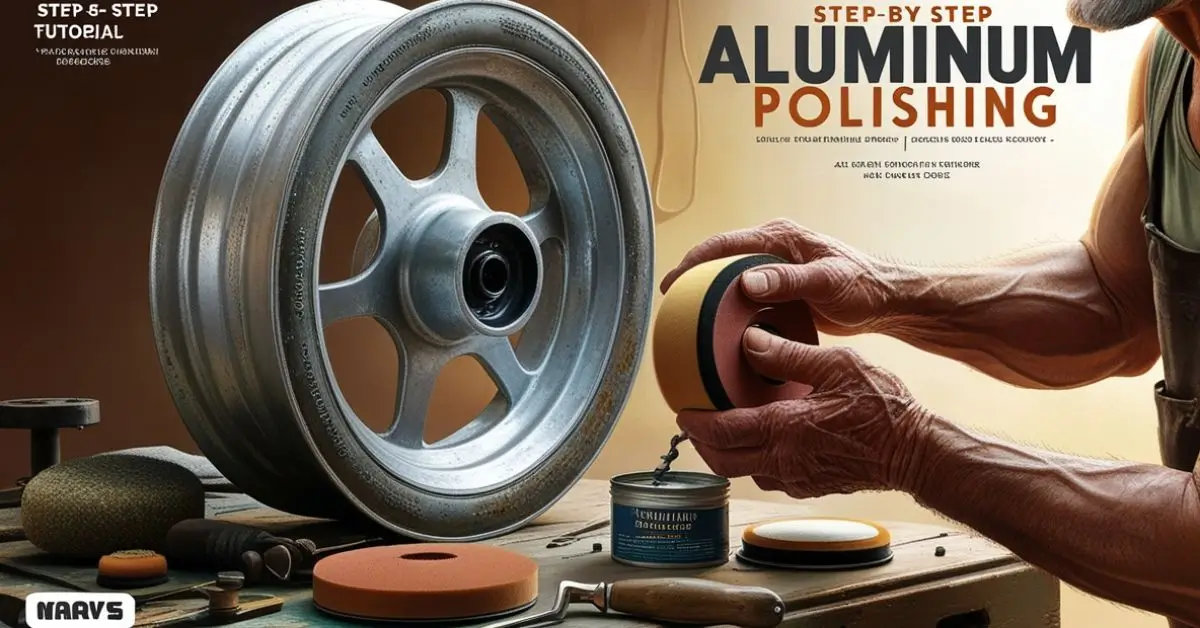

Aluminum is a versatile metal used in various applications, from kitchenware and automotive parts to aircraft components and decorative items. Its lightweight properties, strength, and resistance to corrosion make it an excellent choice for both industrial and everyday products. However, aluminum can lose its luster over time due to oxidation, dirt, and exposure to the elements. This article will guide you through the process of polishing aluminum to restore its shine and beauty, helping you maintain your aluminum products in top condition.

Understanding Aluminum

Before diving into the polishing process, it’s essential to understand the nature of aluminum. Unlike some metals that rust, aluminum develops a thin layer of aluminum oxide when exposed to oxygen. While this layer protects the metal from further corrosion, it can give the aluminum a dull, tarnished appearance. Polishing aluminum involves removing this layer and any surface imperfections to reveal the shiny metal underneath.

There are different types of aluminum finishes, such as anodized, brushed, and polished. Each requires slightly different care when it comes to polishing. In this article, we will focus on bare aluminum, but the general principles can apply to other types as well.

Tools and Materials Needed for Polishing Aluminum

Polishing aluminum requires specific tools and materials to achieve the best results. Before starting, gather the following:

Tools:

- Electric drill or rotary tool: A polishing tool like an electric drill or a rotary tool with polishing attachments will save time and effort.

- Polishing pads and buffing wheels: These are essential for applying polish and achieving a uniform finish.

- Microfiber cloths or soft rags: Use these for cleaning and final polishing.

Materials:

- Aluminum polish or metal polish compound: You can use a commercial aluminum polish like Mother’s Mag & Aluminum Polish or a DIY polishing compound.

- Sandpaper (various grits): Start with coarse sandpaper (around 400 grit) and work up to fine (2000 grit or higher) to smooth the surface.

- Water and mild detergent: A simple soap and water solution is necessary for cleaning the aluminum before polishing.

- Degreaser: For removing any oil, grease, or other contaminants before polishing.

- Rubbing alcohol or acetone: For final cleaning before applying polish.

Preparing the Aluminum Surface

Step 1: Cleaning the Aluminum

Start by cleaning the aluminum surface thoroughly. Use warm water mixed with a mild detergent to remove dirt, grime, and any contaminants that could scratch the surface during the polishing process. If the aluminum is greasy or oily, use a degreaser to remove stubborn stains. After cleaning, rinse the aluminum with clean water and dry it with a microfiber cloth.

Step 2: Inspect for Damage or Oxidation

Once the surface is clean, inspect it for any signs of damage, such as deep scratches, dents, or heavy oxidation. Oxidation on aluminum often appears as white or grayish patches. If you notice significant oxidation or damage, you may need to sand the surface before polishing. Light oxidation can typically be removed with polish, but deep oxidation requires more work.

Step 3: Sanding the Aluminum

For aluminum that has scratches, oxidation, or other imperfections, sanding is necessary to create a smooth surface for polishing. Use different grades of sandpaper, starting with a coarser grit and gradually moving to a finer grit. Here’s a general guideline:

- 400-grit sandpaper: Start with this grit to remove heavy oxidation, deep scratches, or imperfections.

- 600-grit sandpaper: Move to this grit for smoothing out the surface after using the 400-grit.

- 1000-grit sandpaper: Use this grit for further smoothing and preparing the surface for polishing.

- 1500 to 2000-grit sandpaper: Finish with this fine grit to achieve a nearly smooth and shiny surface.

While sanding, use a circular motion and keep the sandpaper wet with water to minimize friction and prevent clogging the paper with aluminum particles. Sanding by hand is effective for small areas, but for large surfaces, consider using a sanding block or an orbital sander.

Polishing Aluminum: The Process

Step 1: Choose Your Aluminum Polish

There are various aluminum polishes available on the market, such as Mother’s Mag & Aluminum Polish, Flitz, or Autosol. These polishes are designed specifically to remove oxidation and restore the natural shine of aluminum. If you prefer a DIY approach, you can make your own aluminum polish by mixing equal parts of water and baking soda to form a paste. While commercial polishes tend to give better results, DIY options can be useful for light polishing jobs.

Step 2: Apply the Polish

Once you’ve chosen a polish, apply a small amount of it to the aluminum surface using a microfiber cloth or polishing pad. Work in small sections to ensure even coverage. Rub the polish into the aluminum using a circular motion, applying light pressure. The goal is to work the polish into the metal and remove oxidation, scratches, and imperfections. As you rub, the polish will turn black as it picks up aluminum particles and oxidation.

Step 3: Buff the Surface

After applying the polish, it’s time to buff the surface to bring out the shine. For large surfaces, use a buffing wheel attached to a rotary tool or electric drill. For smaller areas, a soft cloth or microfiber towel will work. Move the buffing wheel in a circular motion, keeping it moving to avoid creating hot spots on the aluminum.

Buffing will remove excess polish and smooth the surface. As you work, you’ll notice the aluminum gradually becoming shinier and more reflective. Be patient during this step, as it may take several passes to achieve the desired shine.

Step 4: Repeat as Necessary

For heavily tarnished or oxidized aluminum, you may need to repeat the polishing and buffing steps several times to get a mirror-like finish. Reapply the polish, rub it in, and buff the surface until the aluminum reaches your desired level of shine. Each time you polish, the surface should become progressively smoother and shinier.

Step 5: Final Touch: Hand Polishing

Once you’ve achieved a near-perfect shine with the buffing wheel, finish off by hand-polishing the surface with a clean microfiber cloth. This step removes any remaining polish residue and gives the aluminum an extra boost of luster. Gently rub the surface with the cloth in a circular motion, paying attention to any areas that might need a little extra polishing.

Preventing Future Oxidation and Maintaining Aluminum Shine

After polishing your aluminum, it’s important to protect it from future oxidation and keep it looking shiny. Here are a few tips for maintaining polished aluminum:

1. Apply a Protective Coating

To prevent the aluminum from oxidizing again, consider applying a protective coating. Wax, sealants, or clear anodized coatings can help protect the surface from moisture and oxygen, which cause oxidation. Some aluminum-specific polishes even come with built-in protective properties.

2. Regular Cleaning

Regularly cleaning your aluminum with mild soap and water will prevent dirt, grime, and oxidation buildup. Avoid using abrasive cleaners or harsh chemicals that could scratch or dull the aluminum’s surface.

3. Avoid Exposure to Harsh Environments

Whenever possible, minimize your aluminum’s exposure to harsh conditions such as saltwater, extreme humidity, and corrosive chemicals. These elements can accelerate oxidation and tarnishing. If you’re working with outdoor aluminum items, such as patio furniture or car parts, consider using covers when they are not in use.

4. Re-polish When Needed

Depending on how often your aluminum is exposed to the elements, you may need to re-polish it periodically. Light re-polishing with a gentle metal polish can maintain its shine without requiring the more intensive process of sanding and buffing.

Special Considerations for Anodized Aluminum

If you’re dealing with anodized aluminum, the polishing process is slightly different. Anodizing is an electrochemical process that adds a protective layer to the aluminum, often used in architectural and decorative applications. This layer can be damaged by harsh polishing techniques, so it’s crucial to use a polish specifically designed for anodized aluminum.

When polishing anodized aluminum, avoid abrasive tools and compounds. Use a soft cloth and a non-abrasive cleaner or polish. In some cases, it may be necessary to re-anodize the aluminum if the finish has been worn or damaged.

Conclusion

Polishing aluminum is a rewarding process that restores the beauty and luster of the metal. Whether you’re polishing aluminum wheels, kitchenware, or decorative items, the steps outlined in this guide will help you achieve a professional-level shine. With the right tools, techniques, and a bit of patience, you can transform dull, tarnished aluminum into a reflective, eye-catching surface.

Maintaining polished aluminum requires periodic care, but the results are well worth the effort. By applying protective coatings and regularly cleaning your aluminum surfaces, you can extend the life of the polish and keep your aluminum looking as good as new for years to come.